There is no doubt among scientists that climate change is real, and humans are the cause. Since the industrial revolution, the average global temperature has risen by 1° Celsius (C). We already see the effects of this through extreme weather patterns, loss of biodiversity and sea level rise. The Paris Agreement of 2015 set guidelines to keep global temperature rise below 2°C, with a goal to keep the increase under 1.5°C. While global warming at this level will still have detrimental effects on life, the difference between the two is significant. 51 million people live in coastal areas vulnerable to sea level rise if temperatures rise by 1.5°C. This number rises to threaten the lives of 130 million people if temperatures increase by 2°C.

To prevent warming from exceeding 1.5°C, global emissions must be reduced by at least 7.6% every year until 2030. Buildings and construction activities account for 39% of global carbon emissions. Of this percentage, 28% is due to building operations such as heating, cooling and lighting, and 11% is due to embodied carbon related to construction and materials. Although 11% may look small from a global emissions perspective, unless the status quo changes, embodied carbon will be responsible for 72% of all new construction building emissions from now until 2030 [1].

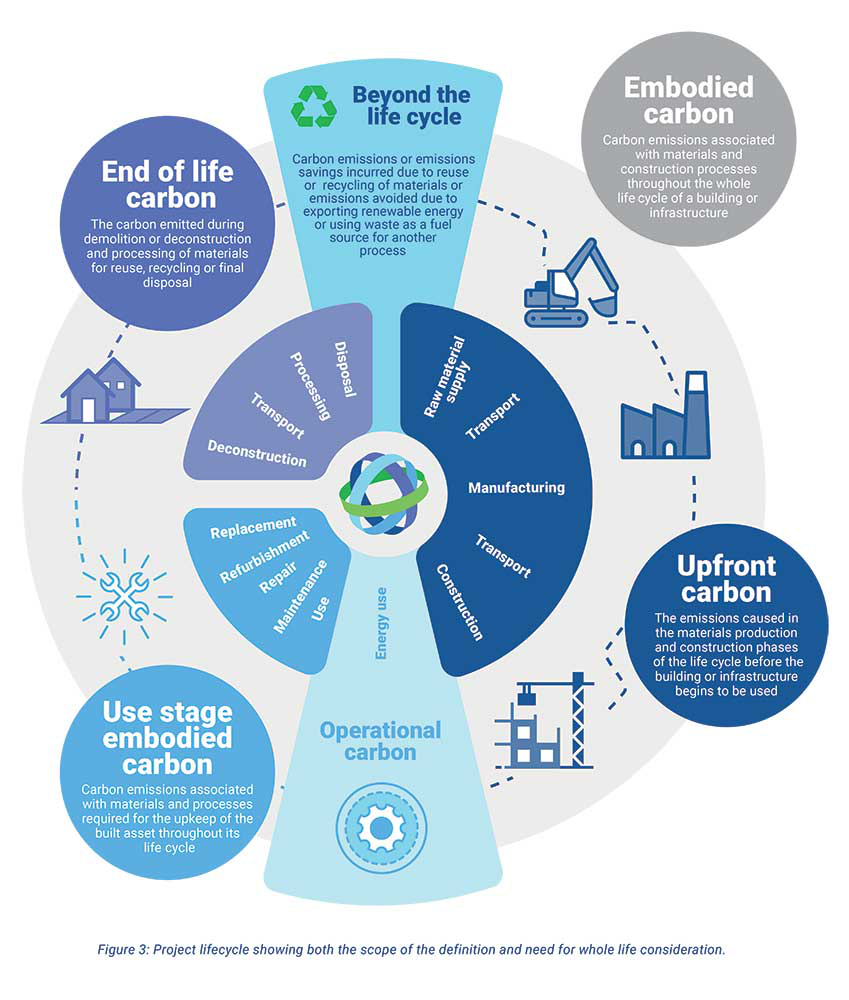

What is Embodied Carbon?

Embodied carbon refers to all carbon dioxide equivalents emitted during the extraction, manufacturing, transportation, construction, maintenance, recycling and disposal of a building’s materials. These actions account, on average, for 20-25% of total CO2 emissions over a building’s life. Hence, a building with a lifespan of 75-100 years will have emitted greenhouse gases equivalent to 20-25 years of operation before it has even been occupied.

According to the European Commission, the global urban population is projected to nearly double by 2050. Infrastructure required to support this expansion will emit over 100 gigatons of embodied carbon alone, accounting for 49% of all building related emissions. Alternatively, given sufficient planning and a commitment to addressing embodied carbon, these buildings could effectively become a carbon sink. The technology exists today to create a building with these negative carbon emissions, in utilizing local and carbon-sequestering materials.

Lowering the Impact of Embodied Carbon

Strategies to lower a building’s embodied carbon emissions must be addressed from the very beginning of design and planning. Most importantly, we must ask if the construction of a new building is truly necessary. If so, can the goal be achieved through renovation or reuse of existing resources? If the acquisition of new materials is necessary, can they be sourced locally?

When new construction cannot be avoided, embodied carbon calculators must be utilized by designers and architects to measure the environmental impact of their building. The use of carbon intensive or carbon sequestering materials must be thoughtfully considered. These calculators use Life-Cycle Assessments (LCAs) and Environmental Product Declarations (EPDs) to calculate the total carbon footprint of a building. Designers can calculate the entire building’s impact; not only in CO2 emissions but other measures, including Acidification, Global Warming Potential, Ozone Depletion, Smog and Eutrophication. This is a free tool which has been created by the Carbon Leadership Forum, which allows for assessment and reductions in the embodied carbon output of a construction project. Another accessible tool is the Athena Sustainable Materials Institute’s Impact Estimator, which allows builders to compare and model over 1,200 different structural and envelope assembly combinations that provides a cradle-to-grave lifecycle view of the building’s impact.

The foundation and structure of a building alone accounts for 80% of its total embodied carbon on average, largely due to the use of concrete and steel. Therefore, instead of razing a building to the ground or starting new construction, architects should consider if there is an existing building or materials that can be reused.

The Impact of Concrete

Concrete is the most used substance on earth after water and has a substantial environmental footprint. Portland cement, which is used to bind concrete together, accounts for a tremendous 5% of total global carbon emissions. Each ton of Portland cement produced releases an equivalent ton of CO2 into the atmosphere. Global demand for concrete continues to grow and accordingly action to reduce its environmental impact must be taken.

CO2 is released from the production of cement in three places: de-carbonization of limestone, kiln fuel combustion, and transportation. Emissions can be lowered by replacing fossil-fuels with renewable energy for heating kilns and transportation. Reducing the amount of clinker, the binding agent, which usually makes up 75% of cement will similarly reduce emissions. There are currently no commercially viable processes to recycle cement paste, the mixture of water and clinker which is created in the cement-making process. Builders must use concrete sparingly and research the various lower-carbon concrete options available today.

Fly ash and slag are both used to improve the carbon footprint of concrete. Fly ash is the mineral residue which results from the combustion of coal in power plants. When reacted with calcium hydroxide, cementitious compounds result. These compounds can be used to replace up to 50% of Portland cement in concrete. Slag is another byproduct which can be used in concrete to lower the amount of Portland cement necessary. It consists of the impurities separated from molten metal when metal ore is exposed to high temperatures. Upon reaction with water, slag develops cementitious properties. The use of slag and fly ash reduces waste sent to landfills and decreases usage of Portland cement.

The Impact of Steel

Steel is used in abundance in commercial construction projects and has a higher embodied carbon impact by weight than concrete. According to the World Steel Association, steel is responsible for 6.6% of global greenhouse gas emissions. The majority of US steel is produced in Electric Arc Furnaces, which use recycled steel instead of iron ore. Using recycled steel reduces emissions by three-quarters in comparison with Basic Oxygen Furnaces, which use virgin ore. Paired with a cleaner electrical grid, the use of Electric Arc Furnaces in North America has resulted in a 36% reduction in the steel industry’s carbon footprint since 1990. Unfortunately, 67% of steel globally is made in Basic Oxygen Furnaces, and over half of the steel used in the US was produced with this technology and imported. If steel can truly not be avoided in construction projects, it is critical that contractors and builders optimize structural efficiency to minimize quantity, source recycled steel, and attempt to buy locally to minimize transportation emissions.

As a last resort, offsetting carbon emissions can help to lower the total embodied carbon emissions of a project. This refers to investing in a project which reduces carbon emissions elsewhere to compensate for unavoidable emissions within the building process. Methods for offsetting carbon emissions include restoring forests, electrifying power plants, or funding renewable energy ventures such as wind farms.

Using Buildings as a Carbon Sink

Mass timber is beginning to be recognized as an effective alternative to steel and concrete in construction. A mass timber building refers to one whose load-bearing structure is comprised of either solid or engineered wood. Building codes have traditionally prohibited wood buildings larger than four to six stories. However, recent mass timber innovations resulting in increased strength and durability of products have allowed wood construction to be used in buildings as tall as 40 stories. Mass timber takes many different forms, created from large structural panels, posts or beams which are constructed using nails, glue or dowels. Surpassing concrete and steel in many ways, there is a great amount of hope among the building community that the use of mass timber could turn future construction into a large carbon sink. According to the Mass Timber Code Coalition, if wood replaced steel on a global scale, it would cut global emissions by 20%. However, the use of stringent regulations regarding timber production is paramount.

The amount of CO2 emitted during the logging, manufacture and transportation of timber must be analyzed before any assumptions about its environmental benefit can be made. The forest industry in Oregon is the largest source of carbon emissions in the state, due to fuel burned by logging equipment, transport, burning of wood and decomposition of trees after they are cut. The Forest Stewardship Council (FSC), is a non-profit which certifies forests meeting their standards of environmentally and socially responsible forest management. They strive to uphold forestry which preserves ecological diversity, benefits local communities and is environmentally sustainable. Despite this, it is complex to track each factor which produces CO2 in forests and production. Approximately half of each tree makes it into mass timber, leaving the rest to rot, releasing sequestered carbon, or be burned to kiln-dry the wood. Furthermore, once a building reaches the end of its life, the way which the wood is either recycled or stored is difficult to predict and vastly affects the carbon footprint of the project. Should the beams be stored, this would need to be done in such a way which would not end up releasing the sequestered carbon.

Despite these challenges, mass timber still holds potential to be a sustainable resource. When harvested responsibly and locally, 1.5kg of CO2 can be sequestered for every kg of wood grown. Without human intervention, trees are carbon neutral, storing carbon as they grow, and then releasing it as they decompose. When we harvest wood to use in construction, this carbon is stored further, and does not return to the atmosphere for decades. Fast-growing trees are more sustainable, as they more quickly store carbon, are harvested and replanted. A greater demand in wood for mass timber would further increase the number of trees being grown in the US.

Instigating Real Change

New construction is expected to double the global building stock between now and 2060. If business continues as usual, this expansion will result in over one hundred gigatons of embodied CO2 emissions. Alternatively, if advances are made in the way we build, this new construction could serve as a carbon sink. Even still, the Paris Agreement’s guidelines will not be achieved unless these advances are mandated by law. The World Green Building Council (GBC) has set two embodied carbon goals to help meet the standards appointed by the Paris Agreement. By 2030, all new buildings, infrastructure and renovations should have at least 40% less embodied carbon and emit net zero operational carbon. From 2050, all existing buildings should emit net zero operational carbon, and all new construction should have net zero embodied carbon. In order to achieve this, it is imperative that these goals are incorporated into the building codes and regulations of towns and cities across the globe. Policymakers at all levels must take action in moving the construction industry towards low embodied carbon and carbon negative buildings.

Is decarbonizing the entire building sector truly within our reach? Consider how much action across the globe has been initiated in the last three months alone, due to the outbreak of COVID-19. Global warming is not such a tangible or quick-acting threat as a virus; there is no cure which once discovered, will solve the pandemic of climate change. Yet, failure to respond effectively to our climate emergency will irreversibly alter the face of our planet. If we wish to reverse the trend of global warming and protect the future of life on Earth, drastic change must occur. All resources necessary to revolutionize the way we build are available today. As operational carbon has been addressed by policy, embodied carbon must be equitably contended.

To learn more about this topic, visit The Carbon Leadership Forum.